Motivation #

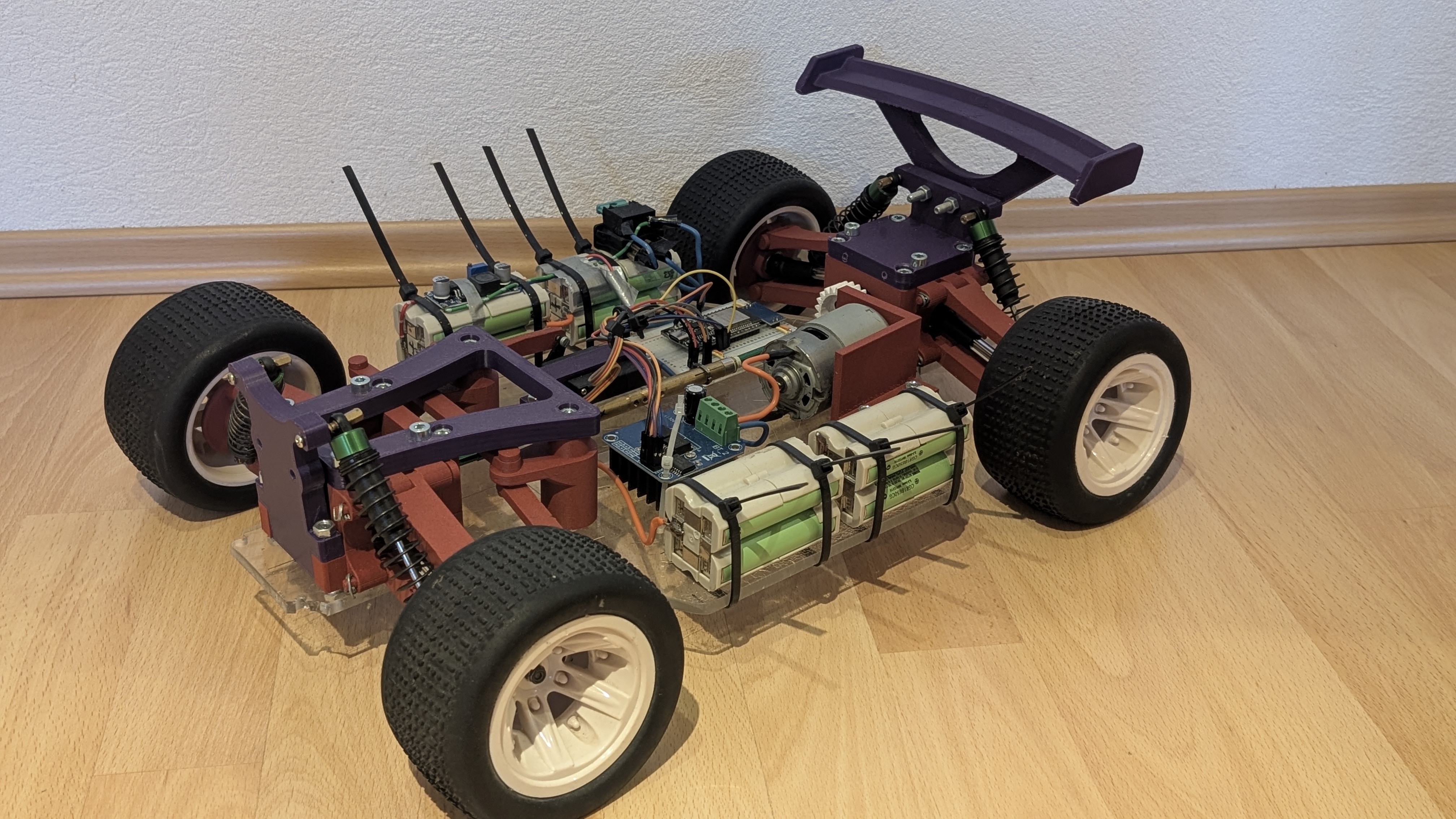

This project was completed as part of a school assignment. The goal was to design, 3D print, and program a fully remote-controlled car from scratch, working in teams of two. The project combined mechanical design, electronics, and software development, providing hands-on experience across multiple engineering disciplines.

Design #

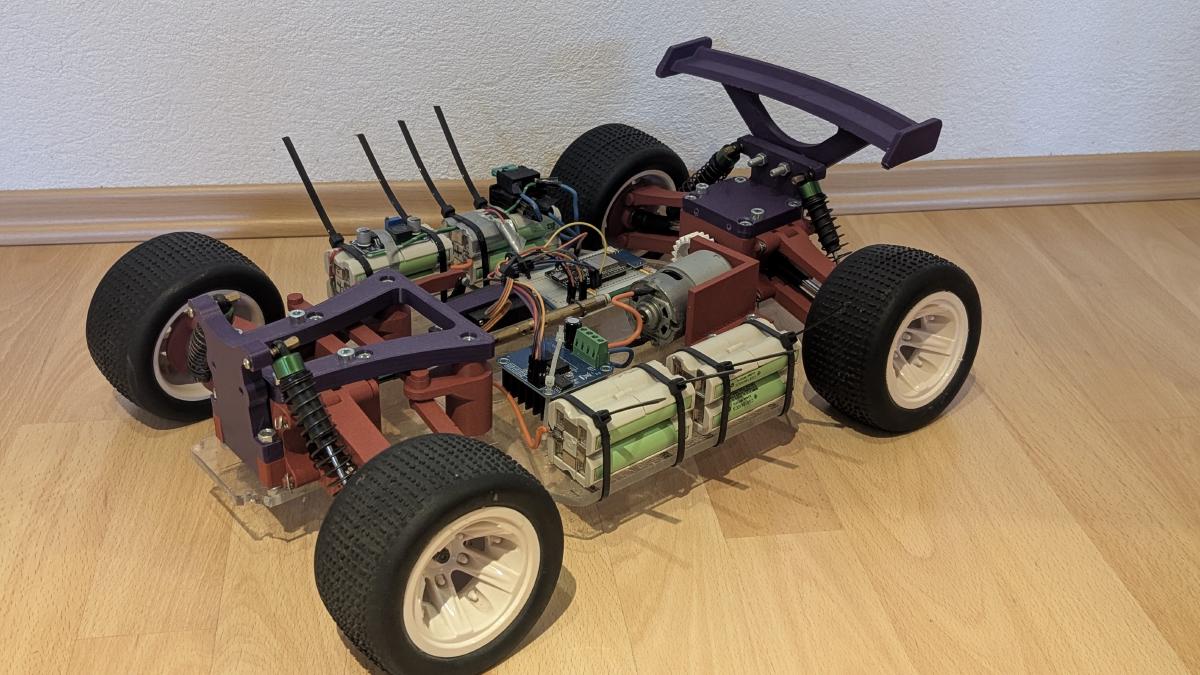

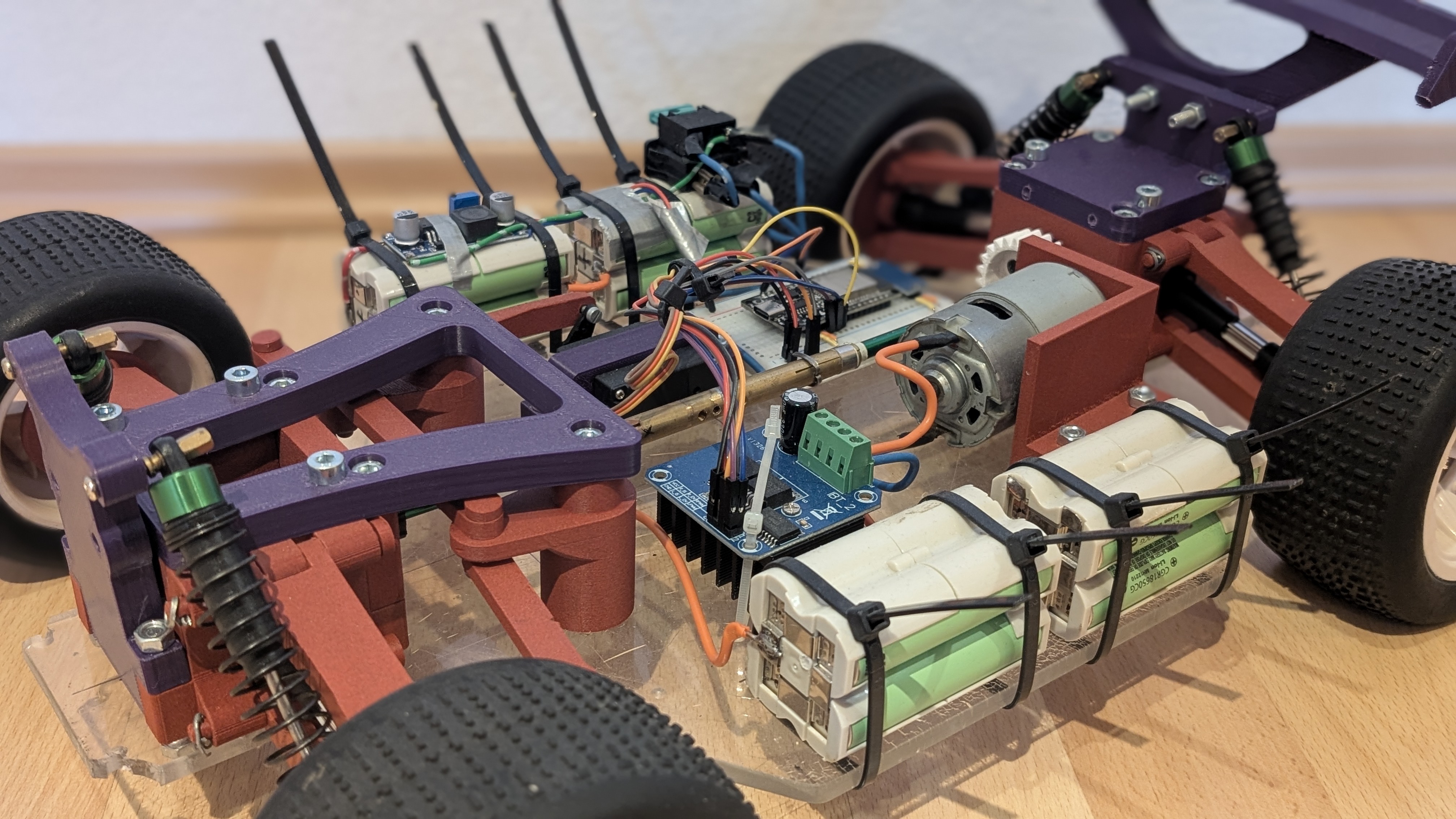

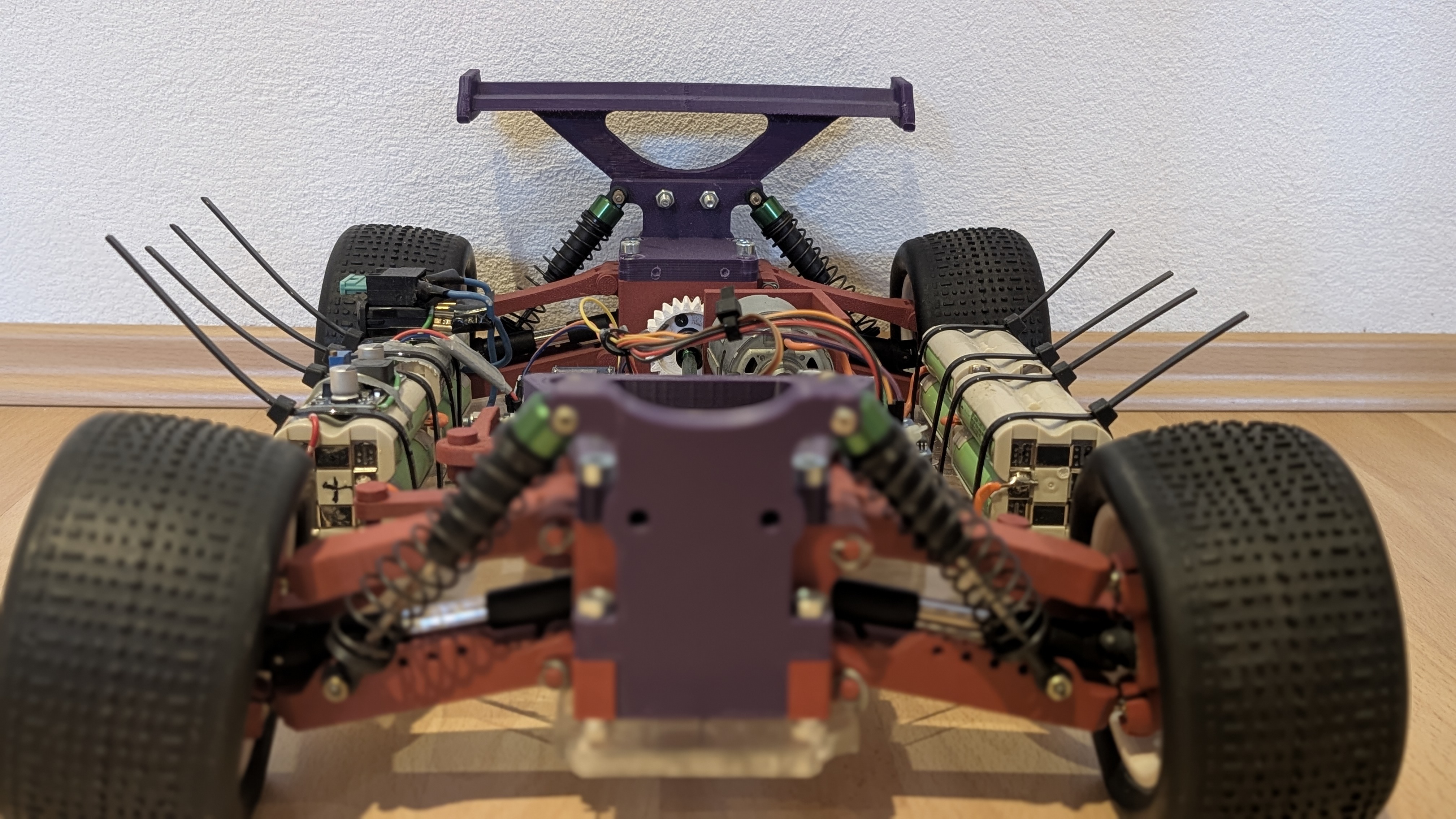

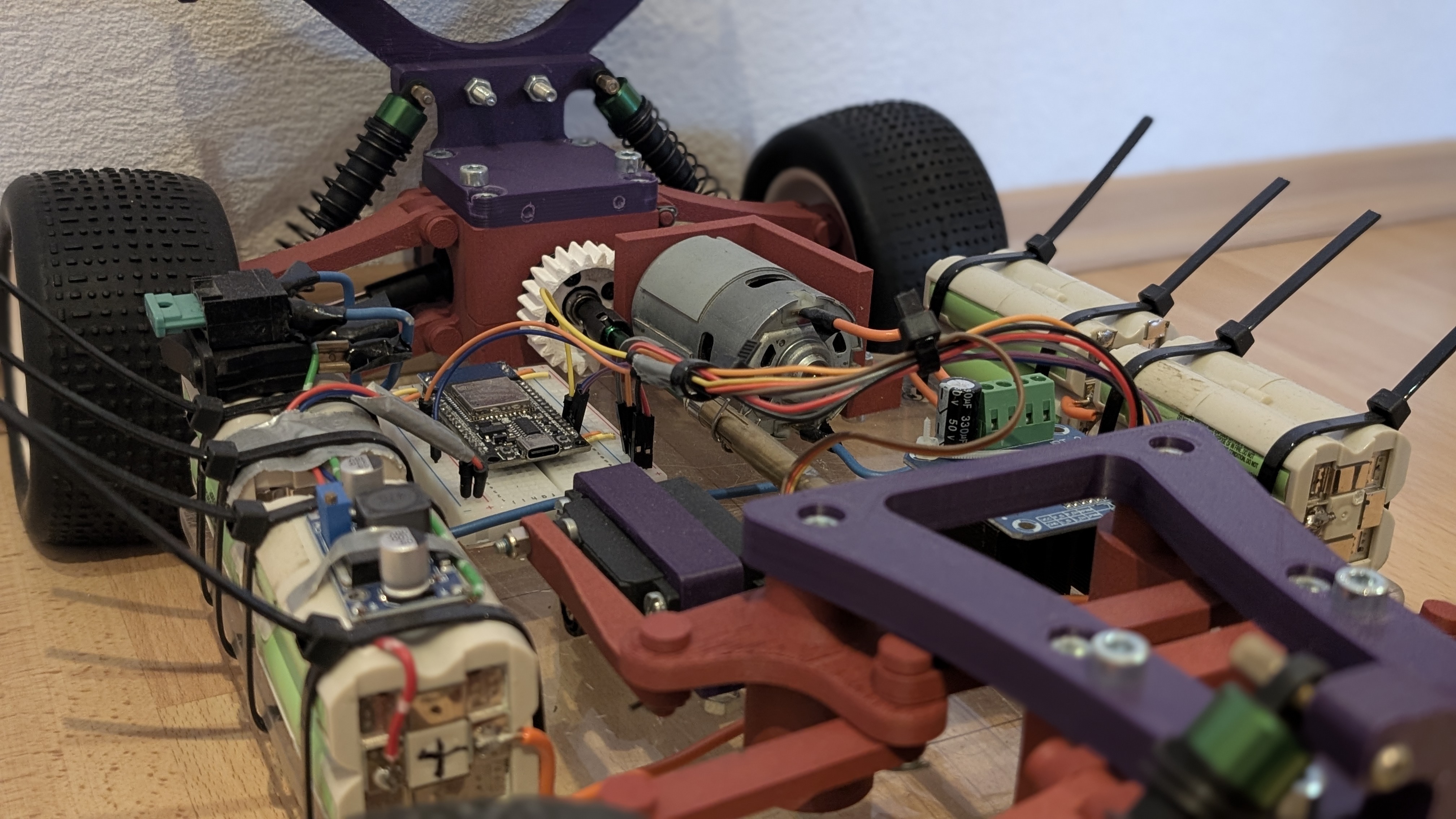

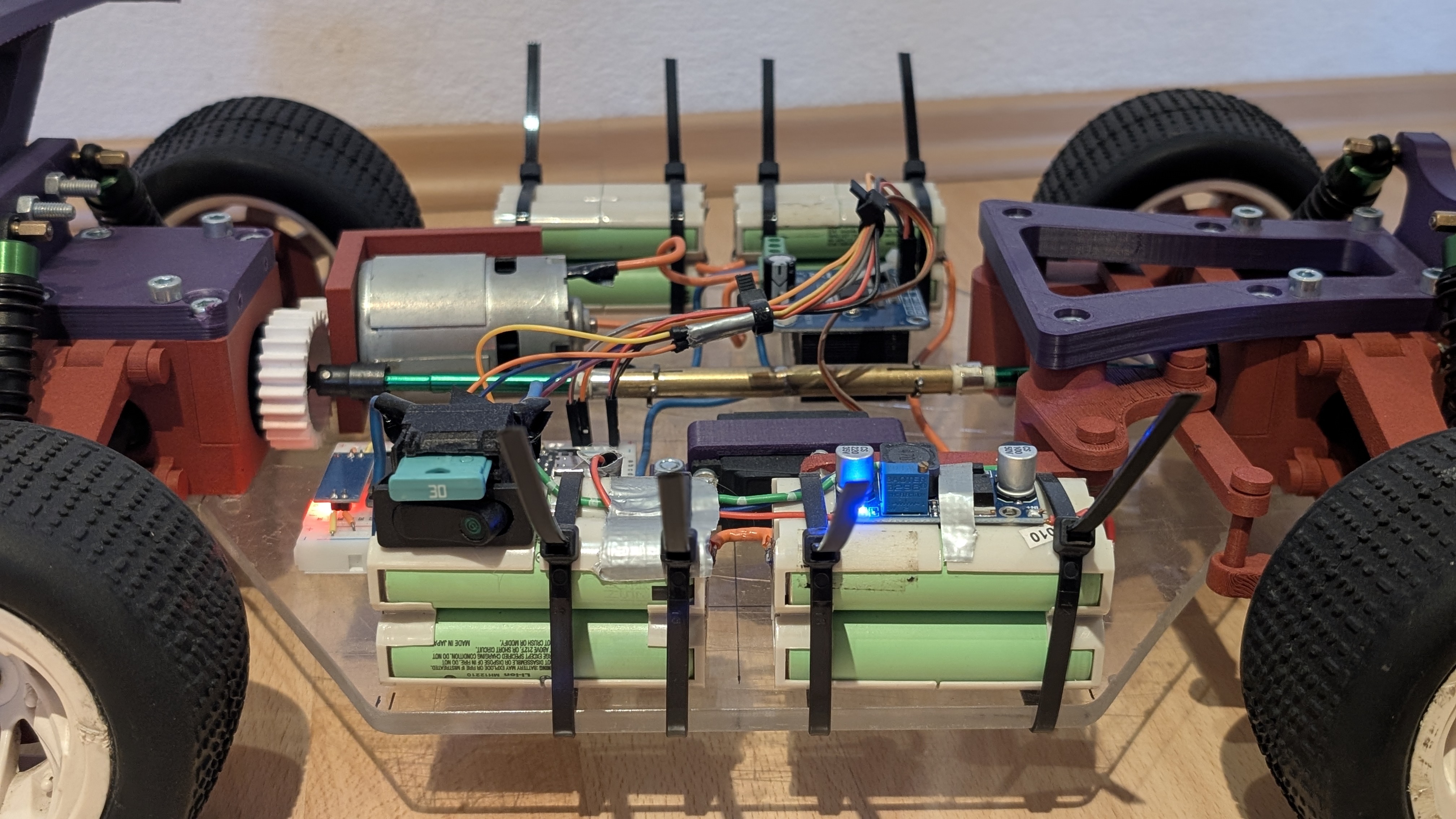

We decided to take inspiration from real RC car designs and disassembled an existing model to study its construction. Reusable components such as the differentials, dampers, and axle parts were salvaged, reducing the need to purchase these parts separately. For propulsion, we repurposed a DC motor from an old Dyson vacuum cleaner, which turned out to be extremely powerful. Power was supplied by four Li-ion batteries, resulting in a combined voltage of approximately 16 volts. All remaining components, including the motor controller, steering servo, and microcontroller, were purchased new.

Manufacturing #

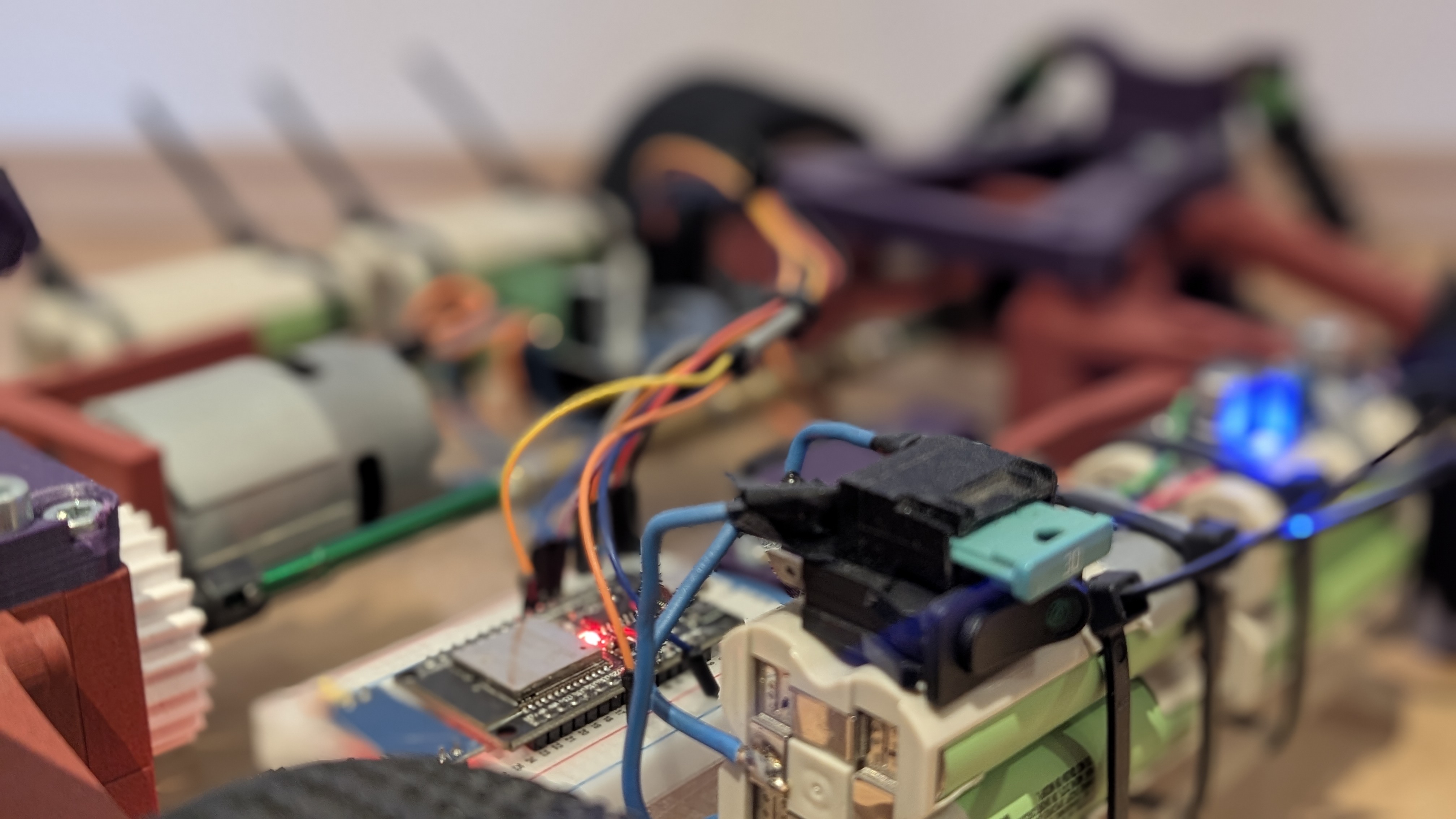

First, all custom parts were 3D printed using carbon fiber–reinforced PLA from Bambu Lab. The baseplate was cut from acrylic glass. After drilling the required holes, all mechanical parts were assembled and secured with screws. The electronic components were then soldered together. Thicker wires were used for high-current paths, as the motor draws significant current under load.

Programming #

An ESP32 microcontroller was used together with the Bluepad library to control the car via a PlayStation 4 controller over Bluetooth. Development was done using the Arduino IDE. After completing the software, the car was tested in multiple trial runs. Once safety and reliability were confirmed, we participated in the final race, successfully completing the project.